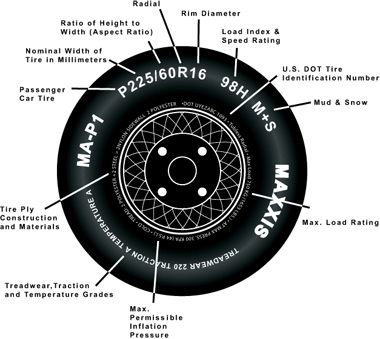

Federal law requires tire manufacturers to

place standardized information on the sidewall of all tires. This information

identifies and describes the fundamental characteristics of the tire and also

provides a tire identification number for safety standard certification and in

case of a recall.

Tire Sizing

P: Vehicle Type

The "P" indicates the tire is for passenger vehicles.

LT: Vehicle Type The "LT" indicates the tire is for light truck vehicles.

215: Tire Width This three-digit number gives the width in millimeters of the tire from sidewall edge to sidewall edge. In general, the larger the number, the wider the tire.

65: Aspect Ratio This two-digit number, known as the aspect ratio, gives the tire's ratio of height to width in percentage. Numbers of 70 or lower indicate a smaller sidewall for improved steering response and better overall handling on dry pavement.

R: Radial Ply Construction The "R" stands for radial. Radial ply construction of tires has been the industry standard for the past 20 years.

15: Rim Diameter This two-digit number is the wheel or rim diameter in inches. If you change your wheel size, you will have to purchase new tires to match the new wheel diameter.

95H: Load Index This two or three-digit number is the tire's load index. It is a measurement of how much weight each tire can support.

Index |

Load (lbs) |

Index |

Load (lbs) |

Index |

Load (lbs) |

65 |

639 |

94 |

1477 |

123 |

3417 |

66 |

661 |

95 |

1521 |

124 |

3527 |

67 |

677 |

96 |

1565 |

125 |

3638 |

68 |

694 |

97 |

1609 |

126 |

3748 |

69 |

716 |

98 |

1653 |

127 |

3858 |

70 |

739 |

99 |

1709 |

128 |

3968 |

71 |

761 |

100 |

1764 |

129 |

4079 |

72 |

783 |

101 |

1819 |

130 |

4189 |

73 |

805 |

102 |

1874 |

131 |

4299 |

74 |

827 |

103 |

1929 |

132 |

4409 |

75 |

853 |

104 |

1984 |

133 |

4541 |

76 |

882 |

105 |

2039 |

134 |

4674 |

77 |

908 |

106 |

2094 |

135 |

4806 |

78 |

937 |

107 |

2149 |

136 |

4938 |

79 |

963 |

108 |

2205 |

137 |

5071 |

80 |

992 |

109 |

2271 |

138 |

5203 |

81 |

1019 |

110 |

2337 |

139 |

5357 |

82 |

1047 |

111 |

2403 |

140 |

5512 |

83 |

1074 |

112 |

2469 |

141 |

5677 |

84 |

1102 |

113 |

2535 |

142 |

5842 |

85 |

1135 |

114 |

2601 |

143 |

6008 |

86 |

1168 |

115 |

2679 |

144 |

6173 |

87 |

1201 |

116 |

2756 |

145 |

6393 |

88 |

1235 |

117 |

2833 |

146 |

6614 |

89 |

1279 |

118 |

2910 |

147 |

6779 |

90 |

1323 |

119 |

2998 |

148 |

6944 |

91 |

1356 |

120 |

3086 |

149 |

7165 |

92 |

1389 |

121 |

3197 |

150 |

7385 |

93 |

1433 |

122 |

3307 |

|

|

Note: You may not find this information on all tires because it is not required by law.

Light truck sizes may be shown in two formats:

LT 245/70R16

LT = Vehicle type

245 = Width in millimeters

70 = Aspect ratio

R = Radial construction

16 = Rim diameter in inches

32x11.50R16 LT

32 = Diameter in inches

11.50 = Width in inches

R = Radial construction

16 = Rim diameter in inches

LT = Light truck tire

Tire Speed Rating Chart

The rating system shown indicates the top speed for which a tire is certified. It does not indicate the total performance capability of a tire.

The speed rating denotes the speed at which a tire is designed to be driven for extended periods of time. The ratings range from 31 miles per hour (mph) to 188 mph.

Note: You may not always find this information on all tires because it is not required by law.

Rating Symbol |

Speed (km/h) |

Speed (mph) |

B |

50 |

31 |

C |

60 |

37 |

D |

65 |

40 |

E |

70 |

43 |

F |

80 |

50 |

G |

90 |

56 |

J |

100 |

62 |

K |

110 |

68 |

L |

120 |

75 |

M |

130 |

81 |

N |

140 |

87 |

P |

150 |

93 |

Q |

160 |

99 |

R |

170 |

106 |

S |

180 |

112 |

T |

190 |

118 |

U |

200 |

124 |

H |

210 |

130 |

V |

240 |

150 |

W |

270 |

169 |

Y |

300 |

188 |

ZR |

Over 240 |

Over 150 |

M+S = Mud and Snow

The "M+S" or "M/S" indicates that the tire has some mud and snow capability. Most radial tires have these markings; hence, they have some mud and snow capability.

U.S. DOT Tire Identification Number

This begins with the letters "DOT" and indicates that the tire meets all federal standards. The next two numbers or letters are the plant code where it was manufactured, and the last four numbers represent the week and year the tire was built. For example, the numbers 1301 mean the 13th week of 2001. The other numbers are marketing codes used at the manufacturer's discretion. This information is used to contact consumers if a tire defect requires a recall.

For example: DOT "UYZEDBC1301"

-

UY: Plant code

-

ZE: Tire size

-

DBC: Compound structure code (Optional)

-

13: The week manufactured

-

01: The year manufactured

Tire Ply Construction and Materials Used

The number of plies and cords indicates the number of layers of rubber-coated fabric or steel cords in the tire. In general, the greater the number of plies, the more weight a tire can support. Tire manufacturers also must indicate the cords used in the tire, which include steel, nylon, polyester, and others.

Maximum Load Rating

This number indicates the maximum load in kilograms or pounds that can be carried by the tire.

Maximum Permissible Inflation Pressure

This number is the maximum amount of air pressure that should ever be put in the tire under normal driving conditions.

What is UTQG?

UTQG stands for the Uniform Tire Quality Grading system.

To help consumers compare a passenger car tire's treadwear rate, traction performance, and temperature resistance, the federal government requires tire manufacturers to grade tires in these three areas. This grading system, known as the Uniform Tire Quality Grading System, provides guidelines for making relative comparisons when purchasing new tires. You also can use this information to inquire about the quality of tires placed on new vehicles.

Although this rating system is very helpful when buying new tires, it is not a safety rating or a guarantee of how well a tire will perform or how long it will last. Other factors such as personal driving style, type of car, quality of the roads, and tire maintenance habits have a significant influence on your tire's performance and longevity.

Treadwear grades are an indication of a tire's relative wear rate. The higher the treadwear number, the longer it should take for the tread to wear down. For example, a tire grade of 400 lasts significantly longer than a tire grade of 200

Traction grades are an indication of a tire's ability to stop on wet pavement. A higher graded tire should allow you to stop your car on wet roads in a shorter distance than a tire with a lower grade. Traction is graded from highest to lowest as "AA," "A," "B," and "C."

Temperature grades are an indication of a tire's resistance to heat. Sustained high temperature (for example, driving long distances in hot weather), can cause tire failure. From highest to lowest, a tire's resistance to heat is graded as "A," "B," or "C."

Example:

View the

Tire Inspection Chart for information on how to identify abnormal tread

wear, sidewall damage, tire separations, road hazards and bead problems.

When purchasing

new tires, it is recommended the tires be mounted by a professional; do not

attempt to mount them yourself. Serious injury could result from a tire being

mounted improperly. While mounting new tires, the dealer can inspect the

vehicle, rim, brakes, etc., for any potential problems as well as recommend the

proper inflation, correct positioning, and correct tire size.

Maxxis

recommends that P-Metric automotive tires never be used as replacements for

Light Truck tires or on a vehicle that is equipped with dual rear tires. Each

tire is manufactured with specific speed rating and load requirements to ensure

proper vehicle use.

In some cases, the tire width might need to

be measured. Before the measurement is taken, Maxxis recommends the tire be

mounted on the rim recommended by the Tire and Rim Association (T&RA) for

accurate measurement.

If the tire is

mounted on a rim that is too narrow, the tire will have a measurement that is

too narrow. This could possibly put an increase of force on the shoulder of the

tire, resulting in tire damage. If the tire is mounted on a rim that is wider

than recommended by the Tire and Rim Association, the tire will have a flatter

profile, moving the flex point toward the area of the rim. The resulting heat

buildup can cause a decrease in tire life or integrity.

As with any

changes or variations done in regards to tires and rims, always consult with

your certified Maxxis dealer first.

Higher aspect ratios provide a softer ride

and an increase in deflection under the load of the vehicle. However, a lower

aspect ratio, normally used for higher performance vehicles, has a wider contact

patch and a faster response. This results in less deflection under a load,

causing a rougher ride to the vehicle.

Changing to a

tire with a different aspect ratio will result in a different contact patch,

therefore changing the load capacity of the tire. This change in load capacity

should always be taken into consideration when changing tire sizes.

Always refer to your owner’s manual for a

rotation schedule and pattern specific to your vehicle. However, a good rule of

thumb is to rotate your tires about every 6,000-8,000 miles in order to avoid

irregular tire wear.

When tires are unbalanced, ride quality and

tire life are significantly impacted. An unbalanced tire is usually detectable

by vibrations at certain speeds. Typically, the vibration is felt through the

steering wheel, especially at high speeds.

Hitting curbs,

potholes, or other road hazards may create an unbalance in the tire. Tires

should be inspected by a professional as soon as possible to avoid excessive

wear and damage to your vehicle’s front end parts.

Aligning your tires ensures that all of them

are adjusted to travel in the same direction. Improper alignment affects tire

wear, gas mileage, stability, and the overall performance of your vehicle. You

should have an alignment performed on your vehicle about once a year, although

hitting a curb or pothole may throw your alignment out. If this happens, you

should have a tire professional inspect your alignment as soon as possible.

Reasons to

suspect your tires need to be aligned and to have your alignment checked:

Excessive or uneven tire wear Steering wheel pulls to the left or right Feeling of looseness or wandering Steering wheel vibration or shimmy Steering wheel is not centered when car is moving

straight ahead

Proper tire inflation ensures your tires will

perform better, last longer, and increase your gas mileage. Always use a tire

gauge to check the pressure in your tires while they are still cold. It is good

practice to check your pressure at least once a month or before long trips.

Your vehicle

manufacturer will specify the inflation pressure necessary for your OE tires.

Check with your tire dealer if you no longer have OE tires installed.

To ensure Maxxis tires look their best, the

sidewalls are constructed to defend against the elements. To keep them looking

their best, use a mild soap or detergent and a semi-soft bristle brush. To

rinse, use clean, plain water.

IMPORTANT - Make sure you don’t overload

tires. To make certain you’re within safety limits, check the vehicle owner’s

manual to determine the amount of load put on the tires. From there, check the

load limit of the tires that are to be mounted. The load index of the

replacement tires should always meet or exceed the maximum load of the original

tires. The overloading of tires could cause poor vehicle handling, tire failure,

and/or problems with vehicle components or lower fuel mileage.

IMPORTANT – Because of the nature of tire

mounting, Maxxis recommends tires always be mounted by a professional. Make sure

to match tire diameter to rim diameter and mount light truck radials on rims

only approved for that application.

It is our

recommendation that bead sealer not be applied as this can inhibit the seating

of the bead. Lubricate beads and tire rim contact surfaces. Lock assembly on

mounting machine or place in safety cage. Step back, and never exceed the amount

of necessary air pressure to seat the bead. Do not use a volatile substance, a

bead expander, or "O-Ring" to help in seating a bead.

Mounting a tire

to rims can be very dangerous due to the energy stored in compressed air. Only

trained tire professionals using the correct tools, safety equipment, and

procedures should mount tires. Do not re-inflate a tire that has been run flat

or shows any signs of damage. Incorrectly mounted or damaged tires can suddenly

cause tire failure, resulting in injury.

Maxxis strongly urges that all tires mounted

on a vehicle coincide with the recommendations of the vehicle manufacturer.

Also, Maxxis recommends that all tires mounted be of the same type and size.

However, if

different profiles must be used, mount the widest tires in the rear of the

vehicle. For the best handling characteristics, do not mix radial tires with

non-radial tires. Mounting tires of different speed ratings, sizes, or

construction could result in tire failure.

Maxxis recommends tires be removed from the

vehicle when there is only 2/32" of tread depth remaining. All DOT approved

tires in production have a tread wear indicator molded into the tread pattern.

This small piece of rubber appears to be a bridge between two tire grooves, but

is only 2/32” in height. When the top of this indicator is even with the plain

of the tread pattern, the tires should be replaced. Failure to replace tires

with tread depths less than 2/32” could result in accidents due to loss of

traction.

Accelerator: A chemical that is used in rubber compounds.

Adjustment: An allowance given to a customer to be used toward the

replacement of a tire because of warranty issues.

Alignment: Inspection and the possibility of adjusting the caster

camber and toe angles of the automobile’s suspension system in accordance with

the manufacturer’s original specifications.

Antioxidant: A chemical used in rubber compounds that prevents

surface oxidation, chunking, and cracking.

Aspect Ratio: The measurement of a tire’s sidewall height. The

calculation is derived from dividing the section height by the section width of

the tire.

Balance: To ensure weight is distributed evenly around the tire

and rim, resulting in a smoother ride.

Banbury Mixer: A large machine used in the production of

rubber compounds for mixing all of the filler and ingredients together.

Bead: The part of the tire that secures the tire to the rim, normally

constructed from a high grade steel wire and hard rubber compound.

Bead Seat: The section of a rim where the bead of the tire rests.

Belts: These are layers of fabric or steel cords coated in a rubber

compound providing the tire with its strength.

Bias-Ply: A type of construction method used to build tires where

the cords in the body plies are placed diagonally from one side of the tire to

the other, normally from one bead to the opposite bead.

Bladder: A large, rubber, inflatable container used in the tire

molding and curing process of tire production.

Blem of Blemished Tire: A tire which has cosmetic or minor

imperfection but is still considered safe to use.

Bolt Pattern: The pattern of holes on a rim/wheel which the bolts that

mount the wheel to the vehicle are put through.

Camber: The angle of the vertical center of the tire to a vertical line

viewed from the front of the tire.

Camber Thrust: The force created by a tire’s camber.

Carbon Black: Filler used in the rubber compounds. Its primary

function is to be used as reinforcement filler.

Carcass: This is the body that gives the tire its shape.

Carrying Capacity: The amount of load/weight a tire can carry

at its proper inflationary pressure established by the Tire & Rim Association.

Chafer: A rubber-coated, abrasion-resistant material that is used to aid

in preventing a tire’s bead from rim damage and chafing.

Compound: The mixture of ingredients such as natural rubber,

synthetic rubber, carbon black, and chemicals, put together in different ratios

to form the building block from which tires are manufactured.

Contact Patch: The area of the tire that makes direct

contact with the surface of the road.

Cord: The steel or fabric strands that form plies and belts in tires.

Cord Angle: The degree of angle that the cords cross the center line

of a tire.

Crown: The center section (between the tire shoulders) of the tire’s

tread.

Deflection: The change in the tire’s vertical and lateral dimensions

when it is placed under load.

Directional Stability: The tendency for a tire to move in the

direction it is steered to rather than following the contours of the road.

Diameter: The measurement of an unloaded tire from one outer edge

to the opposite edge.

Dynamic Balance: This is the balance of a tire while in

motion.

Eccentric Mounting: A condition where a tire is mounted unevenly

on a rim/wheel.

ETRTO: European Tire and Rim Technical Organization.

Flotation Tire: A tire designed to do minimal damage to the

lawn or soil surface.

Green Tire: A tire that has not yet gone through the process of

vulcanization or curing in the tire molding process.

Grooves: Channels in the tread pattern that allow water to flow

out from underneath the tire for wet weather driving.

Hoop Strength: The strength in the construction of the belt

of a tire is resistant to centrifugal strength, giving the tire stability.

Hydroplaning: A loss of traction of a tire on a road surface caused by

wet weather conditions.

Inflation Pressure: The pressure of air inside the tire.

Innerliner: A layer of rubber inside the tire carcass that retains

the air in a tire.

Load Index: A numbering system that specifies the maximum amount of

weight a tire can carry at the speed indicated by the speed rating.

Load Range:

This term replaces the former ply rating system and provides the load and

inflation limits of a tire.

LT-Metric: A sizing system used for light truck.

Match Mounting: A system of mounting a tire where the high

point of the tire is matched with the low point of a wheel. These spots are

normally designated by a dot or a sticker on the tire and wheel.

Mounting Tires: The action of putting the tire on a rim.

This should only be done by a professional for safety reasons.

M+S, M/S, M&S: A designation of a tire that meets the

requirements given by the RMA to be used in mud and snow conditions.

NHTSA: National Highway Traffic Safety Administration.

O.E.: This refers to the original equipment of the vehicle.

Over Inflation: A tire that exceeds the maximum amount of

air pressure recommended by the manufacturer.

Out of Round: A term used to indicate that the tire is not completely

round.

P-Metric: A tire sizing system where the section width is shown in

millimeters and the aspect ratio, type of construction, and rim diameter are

shown in inches (P215/70R15)

Plies: The layers of rubber-coated fabric or steel cord.

Polyester: This is a synthetic material that is used in the body

ply or belt of a tire.

Polymer: A high molecular weight organic compound made up of many

identical components which link to form a chain through a process called

polymerization.

PSI: A measure of air pressure – pounds per square inch.

Radial: A construction method used to build tires where cords of steel

are coated in rubber and are laid across the crown of the tire at an angle of 90

degrees.

Rayon: A synthetic cord material used in the construction of casings

and belts of a tire.

Retread: A process in which a new tread cap is applied to a

casing of a tire that has been worn down.

Rim: The piece of hardware a tire is mounted on and then placed on

the automobile or truck.

Rim Diameter: The diameter of the rim measured according to the tire

bead heel.

Rim Flange: The outermost edge of a wheel’s rim where additional

weights for balancing the tire are positioned.

Rim Width: The distance between the flanges of a wheel.

RMA: Rubber Manufacturers Association.

Runout: The measurement of the "out of roundness" of a tire that causes

vibration and cannot be balanced.

Section Height: The vertical distance measured from the edge

of the bead to the center of the crown in a tire that is not under load.

Section Width: The measurement of a mounted tire from the

outside of one sidewall to the outside of the opposite sidewall.

Series: The designation of a tire’s aspect ratio.

Shoulder: The section of a tire where the tire tread is adjoined

to the sidewall.

Sidewall: The section of a tire between the bead and the shoulder.

Sipes: Small, thin slots that are molded into the ribs or blocks of a

tread pattern that aid in the traction of the vehicle in wet weather conditions.

Speed Rating: A letter coding system designated by the Tire & Rim

Association indicating the tire’s durability at a particular speed.

Static Balance: A condition in which a mounted tire has even

weight around the wheel's axis when the tire is not in motion.

Steel Belt: A layer of material constructed from steel cords and

normally coated in rubber, placed on top of the casing used in the production of

tires.

Toe: This is the difference between the front and the rear edges of a

tire mounted on an automobile. If the front edges are closer together than the

rear edges, the phrase toe-in is used. If the front edges are farther apart than

the rear edges, it is referred to as toe-out.

Tread: The section of the tire that is in contact with the road

surface.

Tread Life: The length of service, measured in miles, of a tire.

Tread Pattern: This is the configuration of voids, blocks,

grooves, sipes, etc. of the tread constructed to provide some of the

characteristics of a tire.

Tread Void: Areas in a tread such as grooves and channels permitting

water to be moved away.

Tubeless Tire: A tire that does not require an inner tube.

This type of tire construction utilizes an innerliner inside the casing,

preventing air leakage.

Tread Wear Indicators(T.W.I.): Small tread blocks in a tire’s tread

pattern (the void area) measuring 2/32" in height that show when a tire should

be changed.

Tread Width: The measured distance from the outer edge of a tire’s

tread pattern to the opposite edge of the tread pattern.

Under Inflation: A tire that has a lower amount of air

pressure than recommended by the manufacturer.

UTQG: Uniform Tire Quality Grading – A measuring system to compare a

tire’s performance based on test results for treadwear, temperature resistance,

and traction.

Zero Toe: A condition where tires on the same axle are positioned

exactly parallel to each other.

A Maxxis MA-1 should have a UTQG rating of 480 BB and deliver a high level of

mileage expectation along with a smooth, quiet ride. On the other hand, a Maxxis

MA-501 has a UTQG rating of 300 AA and is more in line with the expectations of

a performance tire.

Tire Safety and

Care

To

ensure your safety, Maxxis recommends replacing your tires with the original

size or the size recommended by your automobile’s manufacturer. The "Tire

Finder" locator section of this website only recommends the original equipment

sizes.

To

ensure your safety, Maxxis recommends replacing your tires with the original

size or the size recommended by your automobile’s manufacturer. The "Tire

Finder" locator section of this website only recommends the original equipment

sizes.

Measuring the Width of a Tire

Aspect Ratios

Tire Rotation

Balancing Your Tires

Alignments

Proper Tire Inflation

Cleaning Maxxis Tires

Overloading Tires

Tire Mounting

Consistent Tire Sizing

Tire Wear

Tire Glossary